Explore Vietnam’s Most Modern LNG Facility

Thi Vai LNG Terminal stands as a technological masterpiece in Vietnam’s gas industry. Not only is it the largest and most modern LNG complex in the country but also a clear testament of PV GAS to ushering in a new era of Vietnam’s energy journey.

Located in Cai Mep Industrial Zone, Phu My Town, Ba Ria - Vung Tau, Thi Vai LNG Terminal is strategically positioned to handle large LNG vessels and facilitate the seamless import and distribution of liquefied natural gas (LNG).

This LNG infrastructure was developed by PV GAS in collaboration with the Consortium of Samsung C&T and PTSC. These partners brought extensive experience in constructing similar projects both regionally and globally, meeting the highest international standards.

Thi Vai LNG Terminal was designed by world-class consultants such as Tokyo Gas Engineering and Whessoe with the philosophy of no blowdown and no flaring during operation. These were cutting-edge technologies that had never been seen before in Vietnam. Additionally, most materials and equipment used in the project were imported from leading countries in the LNG industry.

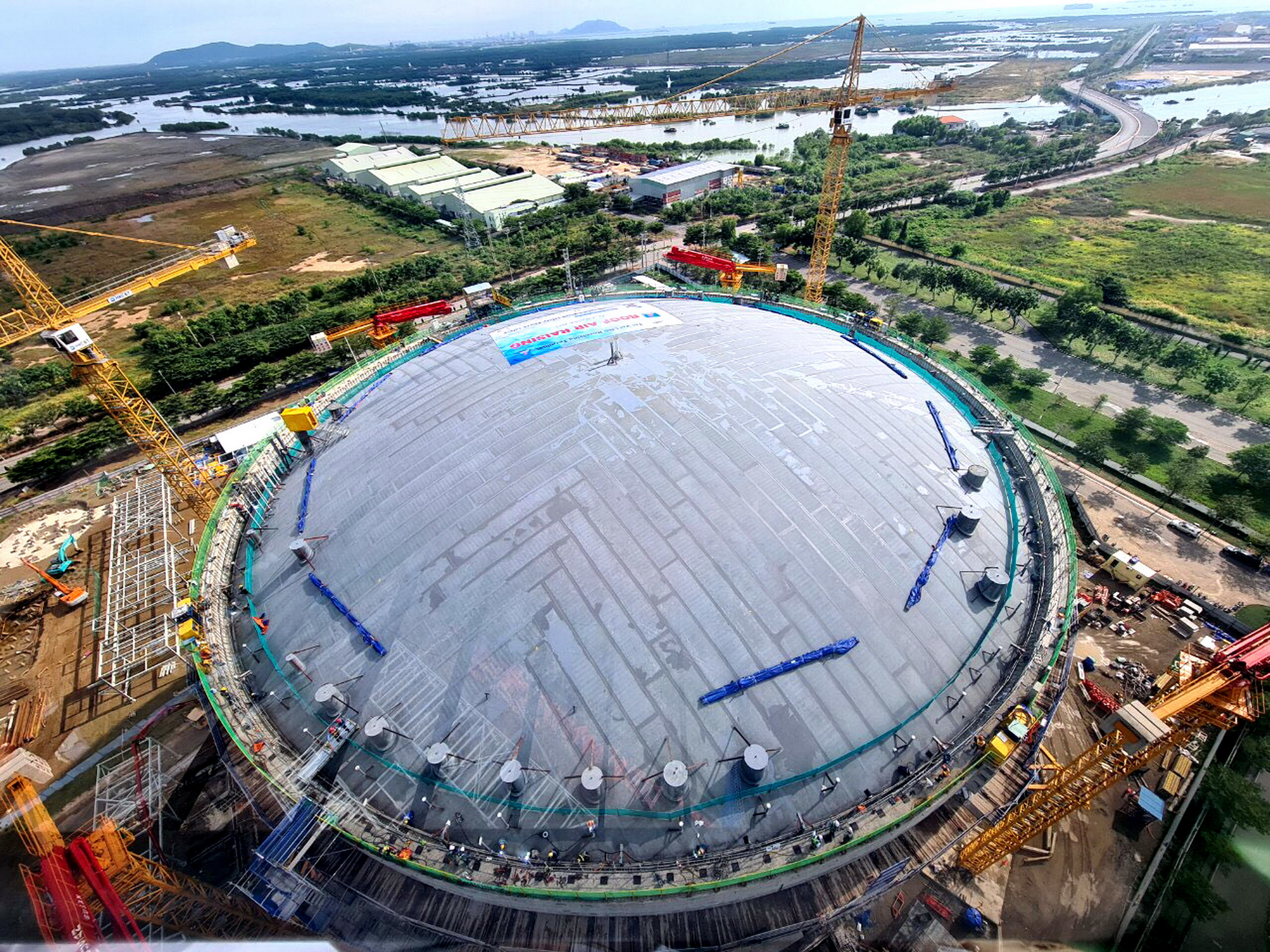

The heart of the site is the LNG storage tank, towering over 50m in height and with an outer diameter of over 2m. The tank is in the form of "Full Containment," constructed with low-temperature resistant steel, prestressed concrete shell, and an inner shell made of 9% Nickel steel material. The tank roof is a steel structure weighing over 900 tons. It was built from the bottom and then lifted to the top, with the "air lifting" technique, before wielded to the outer.

This LNG storage tank complies with stringent standards that ensure safety and quality in the construction and operation of LNG storage tanks, such as API 625, API 620 App Q and ACI 736M-11.

The storage tank is capable of withstanding the extremely low temperature of LNG

The terminal and its maritime system have undergone meticulous assessments, including Dynamic Mooring Analysis, Collision Risk Assessment, and maritime simulations from buoy 0 to the port. These were carried out by top global consulting organizations such as Royal Haskoning (Netherlands), NYK (Japan), ensuring the highest standards of safety and efficiency.

PV GAS offers a variety of transportation methods tailored to each customer's specific needs. Thi Vai – Phu My pipeline, which is 26 inches in diameter and 5.9 kilometers long, connected to Nam Con Son 2 Pipeline – Phase 2 in late 2021, will transport re-gas LNG at high pressure (over 50 barg) from the terminal to consumers. Meanwhile, Thi Vai Low-pressure Gas Distribution Station will supply low-pressure (25 barg) re-gas LNG to customers in industrial zones such as Cai Mep Industrial Zone, Phu My 3 Industrial Zone, and nearby areas. Additionally, an LNG truck loading station at Thi Vai is ready to distribute LNG to low-pressure customers (such as Gas City and CNG Vietnam) and others via distribution lorries.

To ensure safe and efficient operation of the terminal, the entire process of loading, pumping LNG into the tank, regasification, and transportation to customers is strictly monitored and controlled at a central control center. This central control center is equipped with modern monitoring systems.

Central control center

With most of the main technological equipment configured reaching a reliability rate of up to 99.9% and a backup rate of up to 100%, the project has passed all Due Diligences of LNG majors such as Shell, Cheniere, Qatar Gas, etc.

It is expected that after officially operating, Thi Vai LNG terminal will supplement about 1.4 BCM of LNG, compensating for part of the domestic shortage from 2024 onwards.

Thi Vai LNG terminal is considered a testament to the desire, effort, and innovation of PV GAS, as well as a solid foundation, not only meeting the national energy needs but also creating new opportunities in LNG business, contributing to the development of the country and in line with market trends.