The management system of Safety, Health and Environment

PetroVietnam Gas Joint Stock Corporation (PV Gas) is a subsidiary of Vietnam National Oil and Gas Group, operating in the field of gathering, transporting, storing, distributing and trading gas products throughout the country. Currently, PV Gas is managing the operation of three gas pipeline systems: Cuu Long, Nam Con Son and PM3 Ca Mau, with nearly 1,000 km of pipelines, two gas processing plants, six gas distribution centers supplying gas for fuel to 11 power plants to produce more than 40% of national electricity and supplying Liquefied Petroleum Gas (LPG) to more than 70% consuming domestic markets, supplying gas to the fertilizer plant to meet more than 30% fertilizer market and having over 30 facilities, plants consuming low-pressurized gas in the area of Ba Ria - Vung Tau, Dong Nai. The gas projects are located in many different areas such as Ba Ria - Vung Tau, Dong Nai, Ho Chi Minh City and Ca Mau.

In the gas industry, there is always a large volume of gas products during the operation, processing, storage and transport, so potential risk factors on fire always exist. Besides, the gas projects stretch thousands of kilometers and on a wide scale, from the offshore, on shore, to the complex terrain through many rivers, swamps, across several highways, high voltage power lines, etc… where many of the daily activities of people's life take place, so it is easy to generate the potential loss of security and safety on pipeline safety corridor. In addition, in response to the operation, maintenance and repair to maintain the gas pipeline system operating continuously, the employees usually work on high, narrow space, and work near the water’s edge, exposing to toxic chemicals, etc. so the risk of labor accidents and occupational diseases can still occur.

Identifying the potential risks and awareness of the importance of national security and safety for the population of the gas projects, the leaders of PV Gas has determined: Safety is a prerequisite for the existence and prestige of PV Gas.

PV Gas is fully aware that safety is the vital importance of all the activities of the corporation. So, right from the first day of operation, PV Gas has been actively applying the standards of safety management. Specifically, in 1999, with the support and advice of Foster Wheeler, PV Gas has issued more than 700 procedures of operation, maintenance and repair.

In 2003, PV Gas decided develop and apply a management system of Safety - Health according to international standard OHSAS 18001:1999 with a Quality management system according to ISO 9001:2000. PV Gas has issued a policy on Safety – Health – Environment - Quality with the goal of "preventing damage to People, Property and Environment in the production and business activities" and "Satisfying the increasing demands of customers" under the motto "Safety - Quality - Efficiency".

To meet increasing product and service quality in all stages of gathering, processing, storing, transporting and supplying gas products to customers, in 2004 PV Gas began to develop the construction of safety Management system under OHSAS 18001:1999, quality management system according to ISO 9001:2000 and TUV Rheinland certifying company assessed and certified on 17/01/2005.

Photo: PV GAS President and CEO Do Khang Ninh received certificates OHSAS 18001 and ISO 9001 in 2005

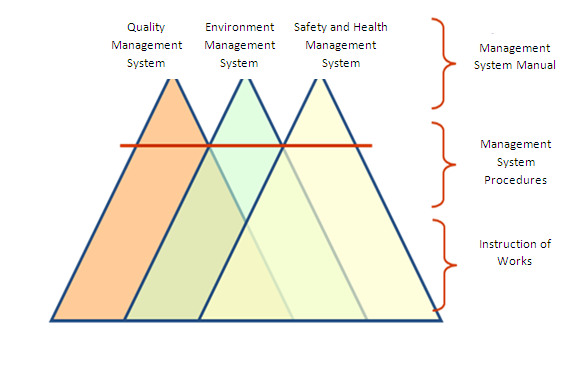

With the goal of sustainable development in the production process and providing its services, PV Gas has been directing to activities aiming at environmental protection. Therefore, along with the maintenance of the management system of Safety and Quality, in 2007 PV Gas continued to build environmental management system under ISO 14001: 2004, integrating into the management system of safety according to OHSAS 18001:2007 and the Quality management System according to ISO 9001:2008. On 5/31/2009, PV Gas has been assessed and granted the certificate by the British Standards Institute (BSI).

The management System of Safety - Quality - Environment of PV Gas is developed on the basis of the systems of international standard OHSAS 18001:2007, ISO 9001:2008 and 14001:2004, and the top experts of the PV Gas on the management system conducted integrating and implementing a system of standard documents, common and consistent with production and business conditions of PV Gas. The Integrated Management System Safety - Quality - Environment of PV Gas includes 15 main documents as follows:

- Policy of Safety - Quality – Environment;

- Handbook

- Risk assessment

- Compliance with Laws

- Emergency Responding

- Accessing to the process and identifying targets

- Responsibility

- Training

- Document and record control

- Safety Inspecting and SQE management system auditing

- Occupational accident investigation and overcoming prevention

- Monitoring, measuring, analyzing and improving

- Leaders’ review

To apply and maintain the management system HQE, PV Gas has issued the policy on Safety - Health - Environment, built the annual Safety – Quality - Environment goal and issued more than 420 control procedures such as risk assessment, safety monitoring and auditing, training and education, quality control ... At the production units, there are over 1,550 procedures on operation, maintenance, ... These procedures are regularly reviewed and updated as appropriate with the changes.

Partly thanks to the successful application and maintenance of the management system Safety – Quality - Environment, for over 15 years of the operation, PV Gas has ensured security, safety, fire protection and maintained the continuous operation, safety and efficiency of gas facilities.